Development of the pressure sensors for the International Habitat Module (I-HAB), the ESA ́ s contribution to the Cislunar Gateway infrastructure as the modular station designed to support the robotic and human exploration of lunar space; supporting its full habitability since the beginning of 2026. The company involvement covers complex pressure sensors development, design, analyses, manufacturing, testing, delivery and support in integration.

Complex solution for in-Orbit demonstration of the Pressure Sensors manufactured by BD SENSORS (BDS) as its long-term core-business production addressing all applications with pressure measurements. Functionality of the pressure sensors experiment is powered by Solar Arrays & Bank of Supercapacitors, as the second experiment of the BDSAT mission. All activities cover the BDSAT development, testing, integration, and support to launch including realisation of both the experiments based on own BDS products portfolio. BDSAT was launched with the Falcon 9 rocket. See www.bdsat.cz.

BDS contribution includes complex Flight Hardware manufacturing of the Filter Wheel Controller including contribution to the design activities in the frame of the „METOP SECOND GENERATION, 3MI Instrument“, FPGA included. This activity includes also full design and MAIT realization of the EGSE FWC Unit Tester including complete Procurement.

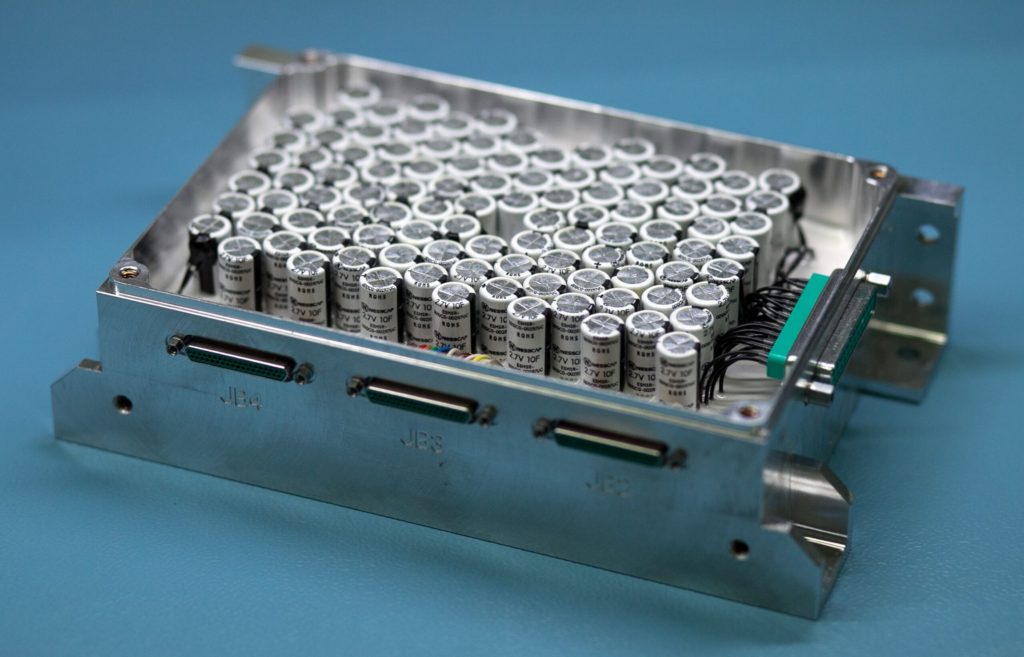

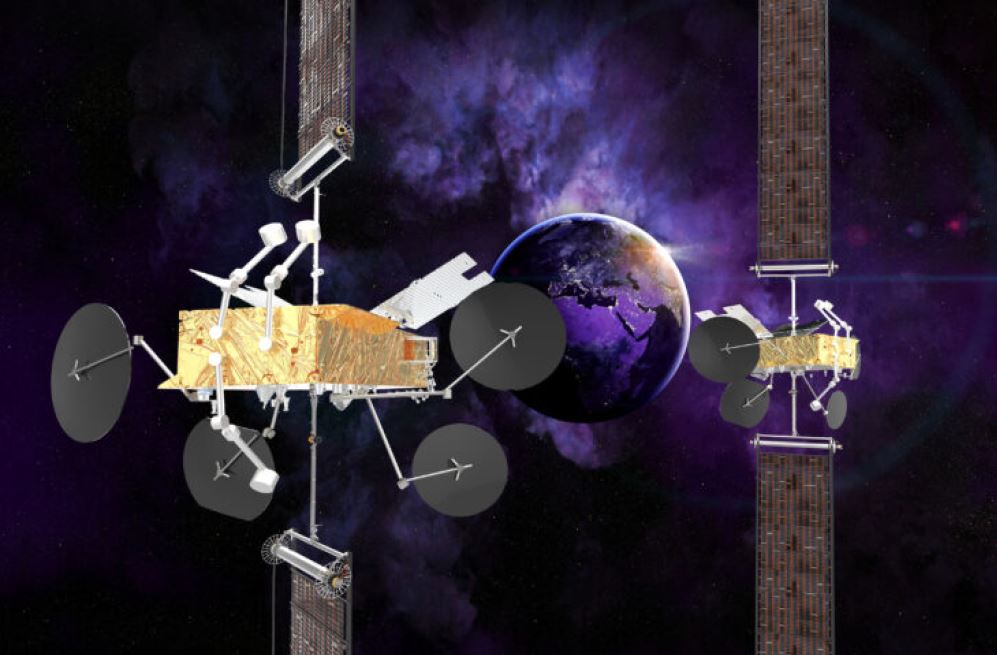

The activities included complete electrical and mechanical development of the Banks of Supercapacitors, as the one of the very first Czech commercial space products ever with followed-up serial production. The BOSCs are addressed to the commercial space market for telecommunication satellites. This unit, replacing heavy and expensive batteries, is well applicable in any application when strong power impulse during a short period is required. Development included a complete set of the EGSE.

In the frame of the FSA project the BDS contribution represents support to design and complete manufacturing of the Electrical Harness and EGSE for the Flexible Solar Array Subsystem. Hardware delivery includes Double Yoke Harness realized as the EM, EQM, and FM sets. The FSA project is realised in the frame of the Czech consortia called BSTG (Brno Space Technology Group = 5M, Frentech Aerospace, BD SENSORS and L.K.Engineering).

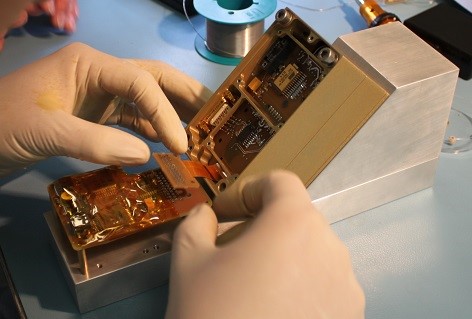

The ECSS-based PCB Assembly is a core business activity since 1996 when CSRC, currently operating as the Space Division of BD SENSORS, has started this challenging manufacturing discipline as the very first private Czech company – a real pioneer in the Czech Republic (CZ). Flight PCB assembly with more than 25 years lasting Space Heritage includes various programs from INTEGRAL, XMM, METOP,…up to SOLAR ORBITER and JUICE. In addition, today BDS is the very first private company in CZ with its own automated SMT technology for PCB assembly for space applications in accordance with the ESA ECSS.

Contribution to the Space Rider / Mechanism Drive Electronics (MDE) is complex manufacturing of the EM, QM and FM boards including support to the design and testing activities. The MDE module controls a set of sophisticated stepper motors to manage opening/closing actions including status monitoring and Communication with the whole system.

The BDS role, as the industrial partner of the IEAP/CTUP, is to co-operate in development, manufacturing, testing of the Radiation Monitor System in a Package called HITPIX including delivery to ESA. It covers consolidate prototype design and manufacturing of the BB, EM, EQM and FM Units. HITPIX monitors the harmful radiation environment around spacecrafts including the flux of neutrons as they pose a significant damage hazard to electronics as well.

Consortium BDS/CSRC and OteSpace has been co-operating in development of the Rocket Engine called PEPE (Peroxide Electric Propulsion Element) since 2016. The PEPE-1kN breadboard developed and tested. It includes bi-liquid rocket engine; storable eco-friendly & user-friendly propellants; electric pumps (simple, reliable, versatile); hypergolic ignition (reliable, repeated restart ability); after ignition the engine switches to a non-hypergolic fuel (enhanced safety and performance); regeneratively cooled chamber and nozzle (reusability); injector with variable wet area (throttling ability). The PEPE-10kN development is in progress.

Complex development including electrical & mechanical design, manufacturing, and testing is another element of the BDS core business. Typical EGSE units contain especially various power supplies, acquisition units, thermocouples, thermo-switches, thermistors, rack with relays, and many other components. Examples of successful EGSE realisation include Thermal Test Benches for NEOSAT AIT Application; Unit Testers for electrical testing of the METOP SG / 3MI / Filter Wheel Controller; testing Banks of Supercapacitors used in telecom spacecrafts; EGSE for controlling nominal and redundant deployment mechanisms for Solar Arrays.

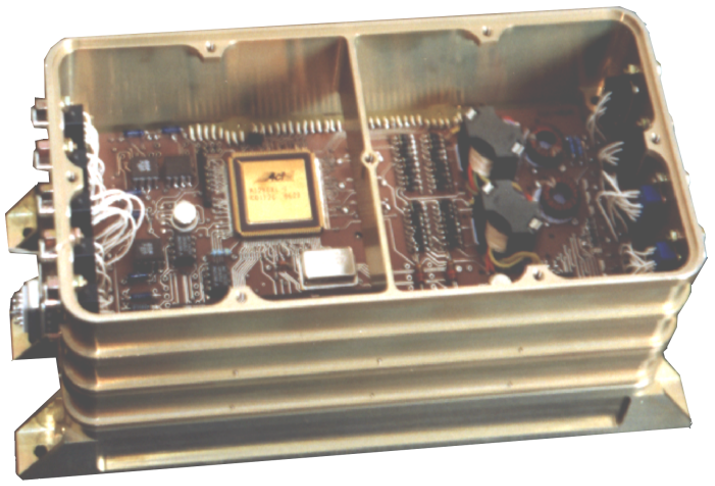

Plastic Scintillator Anti-Coincidence Flight unit for photomultiplier high-voltage control, an experiment for the INTEGRAL (International Gamma Ray Astrophysics Laboratory) satellite for processing of the light emission caused by X ray particles covers development, design, analyses, manufacturing, testing, delivery and support in integration. The PSAC components are the High voltage power supply, the Low voltage power supply and the Electronic control box with the radiation hardened Actel 1280 FPGA.

Interface system for the Langmuir probe is an intelligent interface between the Langmuir probe and the ground system for scientific data acquisition when converting low-current of pA to μA range to voltage. Interface board operation is controlled by the software application with graphical user interface.

Contribution to the first European mission to the Moon covered the design and development of the flight hardware and software for SMART1 satellite, implementation of CAN bus including analyses, manufacturing, testing, delivery and support in integration.

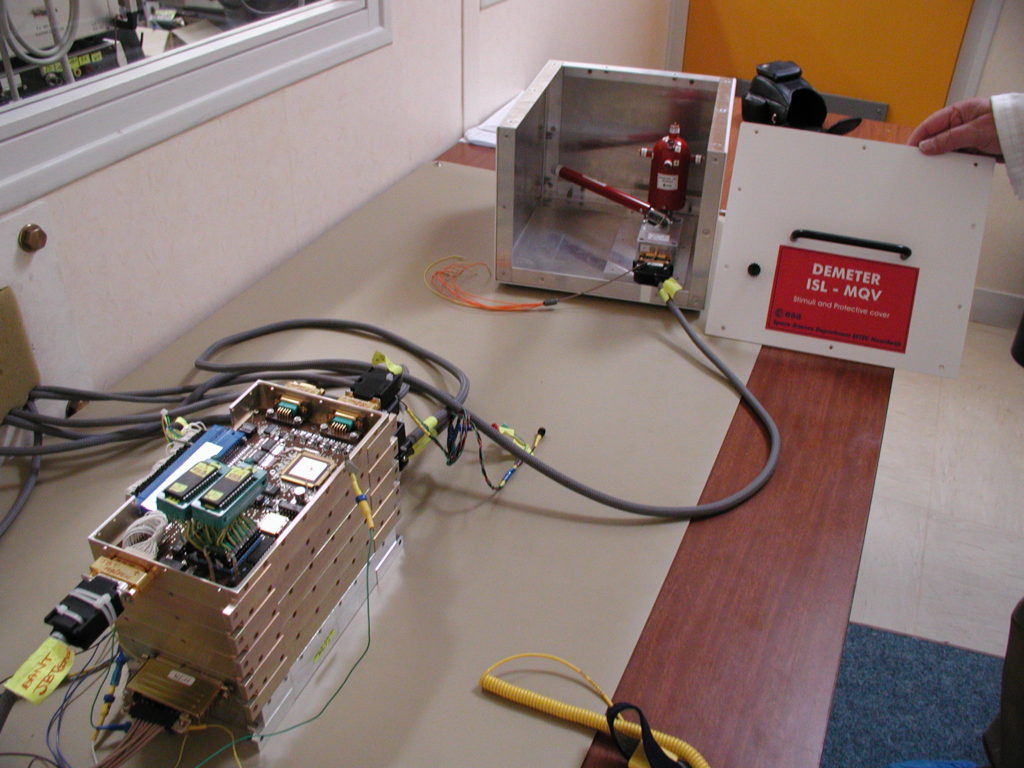

The activities included complete delivery of the electrical and mechanical design including FPGA design, power supply design and all ESA requested tests, simulations and documentations. Two SLP probes (Segmented Langmuir Probe) are dedicated for surround satellite plasma measuring by means of the three TPMU (Thermal Plasma Measurement Unit) process sensors.

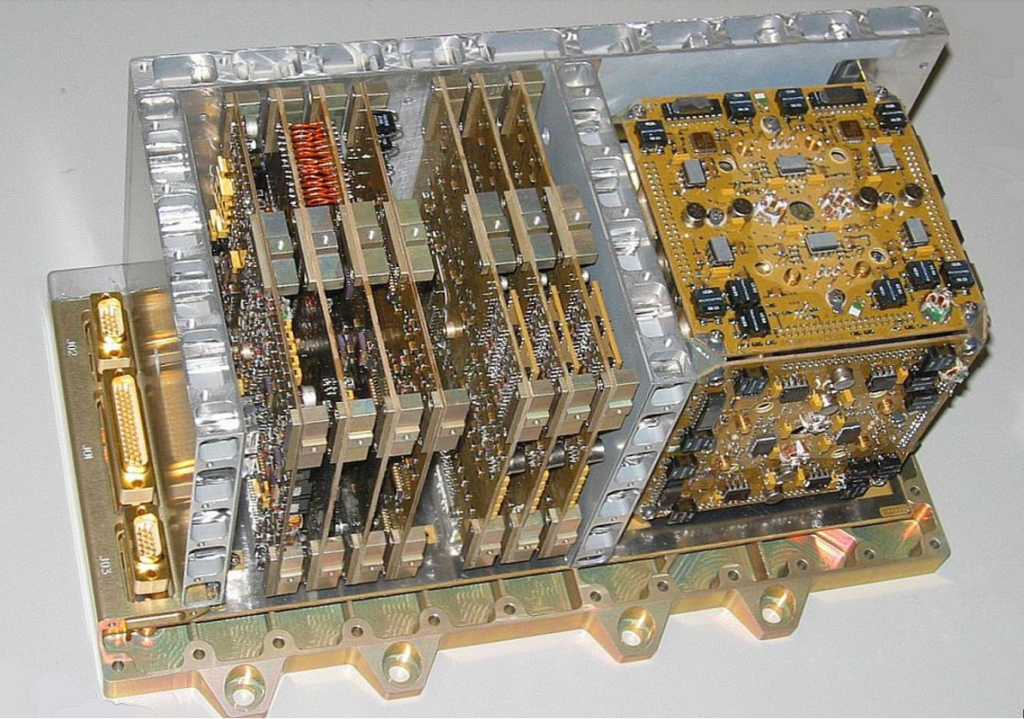

In the frame of the SWARM project the contribution represents all the cleanroom manufacturing activities of the scientific micro-accelerometer. The complete flight hardware includes the EM, EQM, PFM and FM sets, while each set consisted of a total number of 15 PCBs.

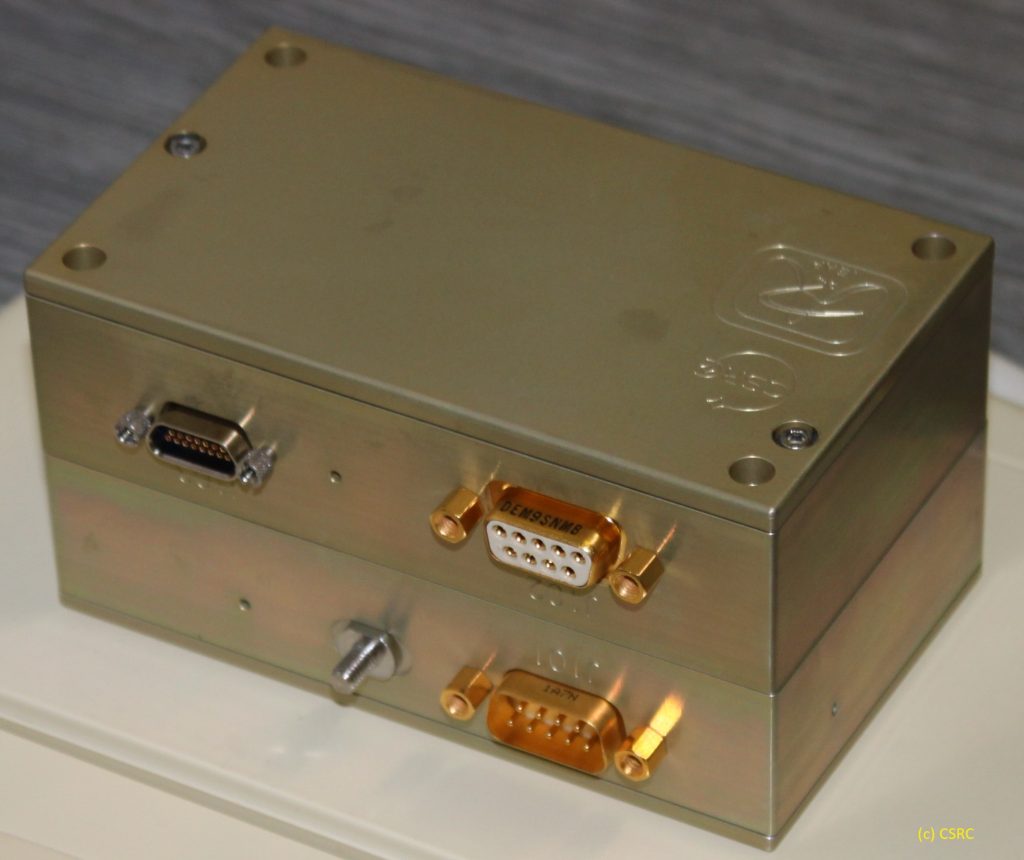

The objective was to launch technology demonstrator flight hardware based on a detector from TimePix family on the Proba-V satellite. The scope of this activity was to provide complex FM design & manufacturing related to the Space Application of TimePix-based Universal Radiation Monitor.

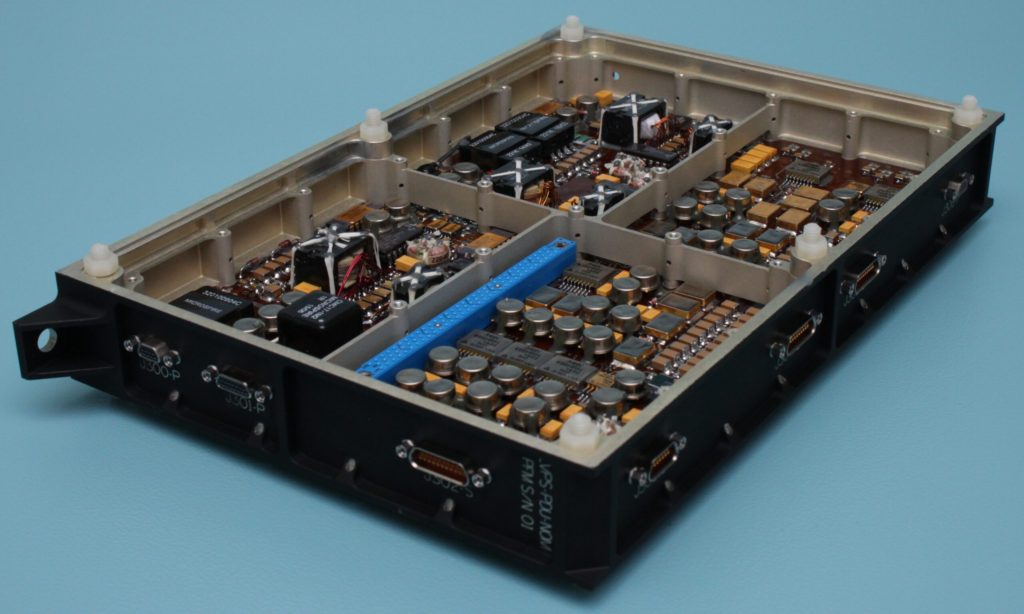

Contribution to both the RPW and the STIX scientific units was complex manufacturing of the EM, EQM and FM Power Supply Modules including support to the design and testing activities. The RPW powering subsystem consists of the Low-Voltages Power Supply (LVPS) and the Power Distribution Unit (PDU). The two units constitute one single module called LVPS-PDU, which is a commonly shared resource within RPW.

Project ELT (European Laser Timing) is purely Czech contribution to important international experiment ACES (Atomic Clock Ensemble in Space). Its major goal is to verify performance of new generation of extremely precise atomic clock in microgravity and to perform independent time measurements on Earth and in space. The ELT device is going to be installed on board the ISS, particularly on the external platform of European Columbus laboratory module. The objective was to provide complex FM design and MAIT of the ELT Instrument including ground stations calibration in the frame of the ESA follow-up activity.

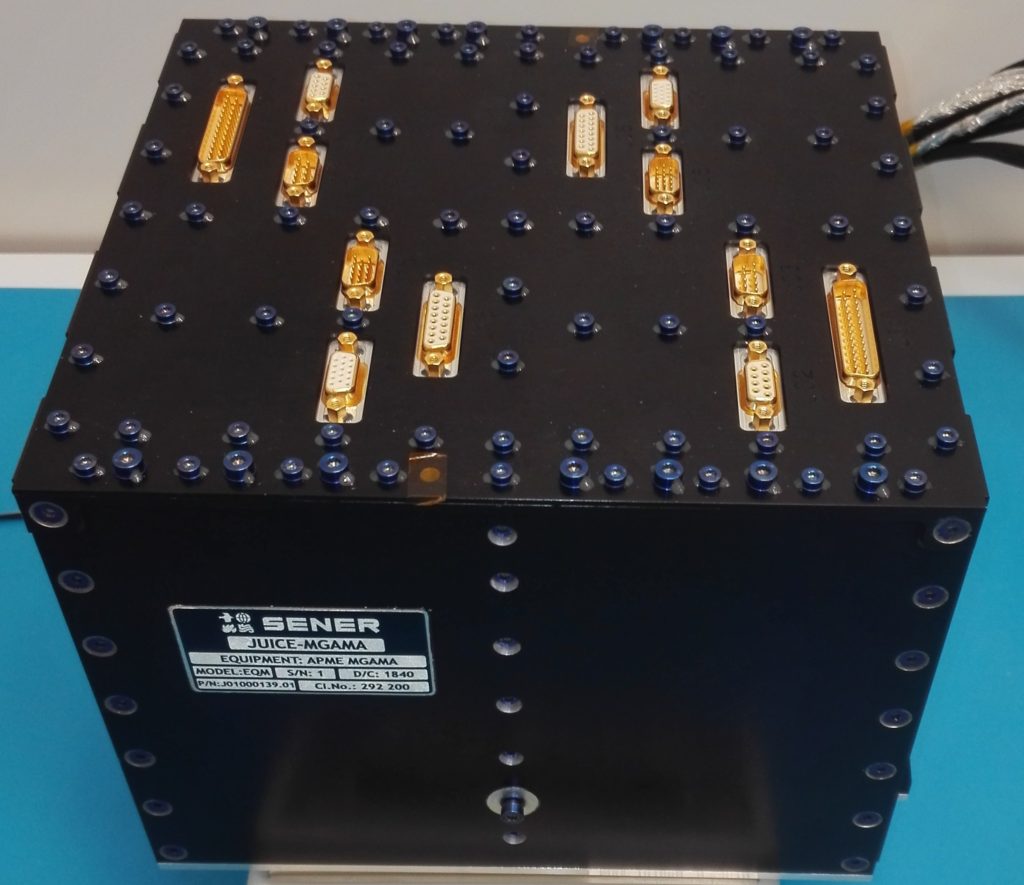

The JUICE main mission will be to explore the huge planet’s three largest icy moons in the hope of determining whether life is possible on these dwarf planets. The project aimed to provide the part procurement, the assembly, integration, and test of the APME / MGAMA for the JUICE Spacecraft. It included all the necessary support during design and development phase and analyses and design validation. It included manufacturing and testing of 34 boards that were integrated in the BBM, EM, EQM, FM, and FS models. Activity included also successful ESA certification for the SMD footprints.

The main objective was to supply 10 pcs of the Thermal Test Benches for NEOSAT AIT Application covering all purchasing, prototyping, support to design and complete responsibility for MAIT activities. The thermal test benches contain various power-specific power supplies, acquisition units, thermocouples, thermo-switches, thermistors, rack with relays and an ACU-T function.